Precision Perfected: Elite CNC Quality Control for AS9100, ISO 13485 & ISO 9001 Excellence

Inspection

Zeiss Contura CMM

MicroVu Excel, 2x MiroVu Sol

5x Starrett AVR 300

Optical Comparitors

HD Cameras

Mitutoyo Profilometers

Deltronic Pin Sets

Laser Micrometer

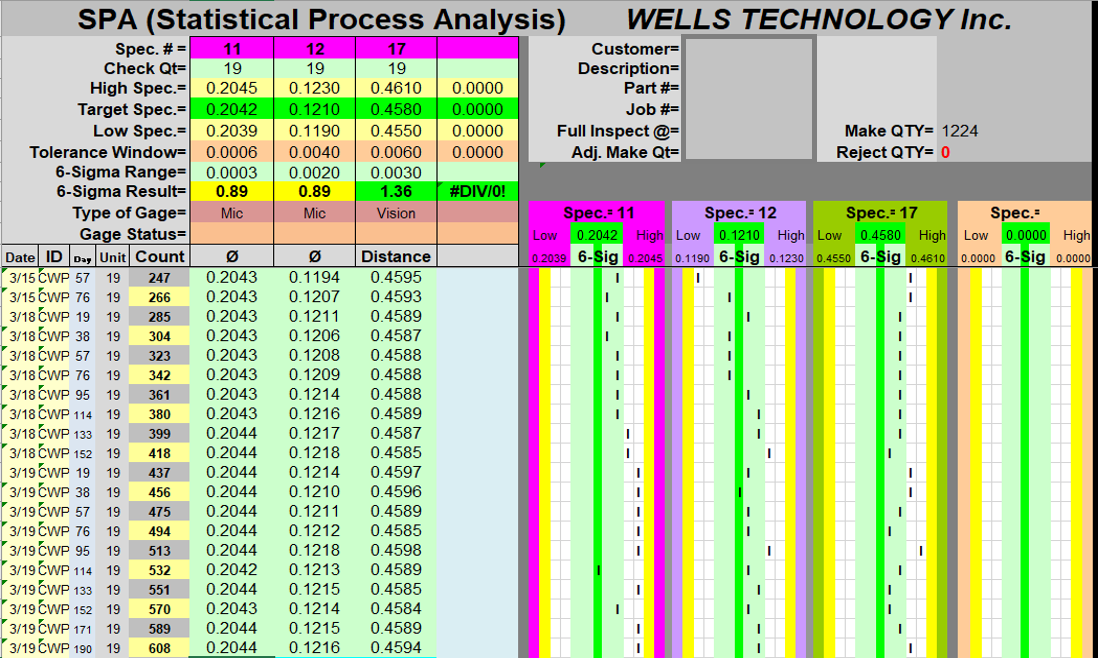

Statistical Procass Analysis (SPA)

High Tech Assurance

-

Starrett AVR 300

The Starrett AVR300 CNC vision metrology system elevates our quality department by delivering precise 2D/3D measurements with micron accuracy. Its MetLogix M3 software ensures fast CAD comparisons and real-time inspections via live video and optical zoom. With LED illumination and CNC controls, the AVR300 optimizes quality assurance, minimizes defects, and boosts throughput, showcasing our commitment to superior CNC-machined parts.

-

Statistical Process Analysis (SPA)

At Wells Technology Inc., we utilize Statistical Process Analysis (SPA) with Six Sigma principles to ensure precision in our CNC machining operations, tracking critical measurements in real-time to alert operators of potential deviations. This visual dashboard enables tight tolerance control and zero rejected quantities in production runs, reflecting our commitment to proactive quality management and delivering consistently high-performance parts that exceed customer expectations.

-

HD Camera

Our CNC machining shop leverages AmScope HD cameras to enhance quality control, ensuring precision in every part we produce. Strategically positioned around our work centers, these high-definition cameras enable operators to closely inspect components for imperfections like burrs, ensuring flawless finishes and tight tolerances. This advanced visual inspection technology boosts efficiency, reduces errors, and guarantees the superior quality our customers expect from our detailed machining processes.