Capabilities

-

Advanced Equipment

Wells Technology Inc. leverages a versatile array of STAR CNC machines to deliver precision components for diverse industries. The SW-12 and SW-20 models excel in crafting small-diameter parts for watchmaking and medical devices, ensuring exceptional accuracy for intricate applications. The SV-20, SR-38, and SK-51 models support complex, high-volume production for aerospace, automotive, and electronics, meeting stringent industry standards with reliability and efficiency. This advanced technology enables Wells to consistently produce high-quality parts tailored to client specifications across multiple sectors.

-

Materials

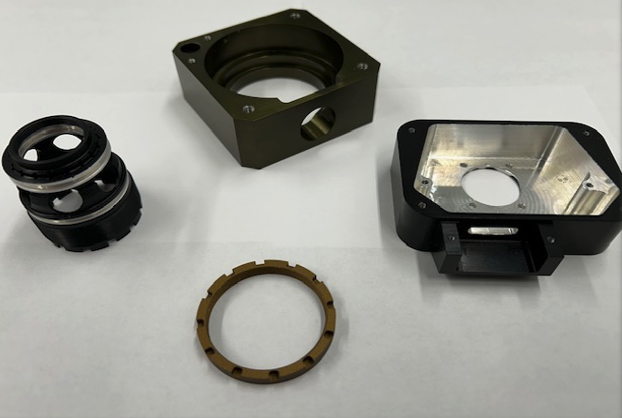

Our CNC manufacturing expertise encompasses precision machining of a diverse range of metals and plastics, tailored to meet the demanding needs of various industries. Our capabilities include working with high-performance materials such as Stainless Steel, Alloy Steel, Tool Steel, Carbon Steels, Inconel, Monel, Hastelloy, Titanium, Niron, A286, Aluminum, Copper, Bronze, and Beryllium. This extensive material expertise allows us to deliver components with exceptional strength, durability, and corrosion resistance, ensuring optimal performance in applications from aerospace to industrial equipment.

-

Processes

At Wells Technology, we ensure the highest quality in every step of our manufacturing process by partnering exclusively with NADCAP-certified suppliers for all secondary processes. This prestigious certification guarantees that our partners adhere to rigorous industry standards, delivering exceptional precision, reliability, and consistency in processes such as heat treating, plating, and non-destructive testing. By leveraging these certified partnerships, we provide our customers with products that meet the most stringent aerospace and industrial requirements, ensuring unparalleled performance and trust in every component we deliver.

Machinery

-

The SW-12RII CNC Swiss-type Automatic Lathe is designed with diverse tooling for complex machining.

SW-12 mm dia. capacity, bar feed, 10-axis live tooling

-

The SW-20 CNC Swiss-type Automatic Lathe features advanced software that improves production output and profitability, next-generation software that reduces idle times, an exclusive tool post design with Y-axis control for machining complex functions independently, a Star Motion Control System for an uninterrupted tool path, and various user control features like manual handle retracting, program check, code help, and alarm help.

SW-20 mm dia. capacity, bar feed, 11-axis live tooling

-

The SV-20R CNC Swiss-type Automatic Lathe is designed for producing intricate parts for medical and aerospace industries, offering a wide range of machining operations with a maximum diameter of 20 mm. It features multi-axis control for high productivity, flexible tooling for complex machining, a "Super position mode" for simultaneous tool operation, an 8-spindle backworking unit with Y-axis control, and the ability to switch between Guide Bush and Non-Guide Bush functions, all enhanced by Star Motion Control to minimize idle time.

SV20R-20 mm dia. capacity, bar feed, 12-axis live tooling

-

The SR-38 Type B 10-Axis CNC Swiss-type Automatic Lathe, utilizing Star CNC technology, is designed for complex machining in industries like aircraft, automotive, and medical. It features rigid construction for handling up to 1-1/2” diameter bar stock, built-in main- and sub-spindles with high tool post rigidity for accuracy, capabilities for two-tool turning and heavy material removal, an 8-spindle backworking unit for producing complex parts in one operation, B-axis versatility, a proprietary Motion Control System that reduces idle time, and is environmentally friendly with low energy consumption.

SR-38 mm dia. capacity, bar feed, 10-axis live tooling

-

Star CNC's SK-51 Type A CNC Automatic Lathe, the first in their new line of fixed headstock lathes, features the advanced Fanuc iHMI control system with smart machining capabilities to guide operators efficiently. It includes twin 12-station turrets for balanced machining, A2-5 spindle chucking for precise part gripping, a slant bed design suited for challenging materials in medical, energy, and aerospace sectors, extensive tooling for complex parts, easy access to spindles and turrets, and a user-friendly touch screen for accessing manuals.

SK-51 turning centers, 2” dia. bar feed, 8-axis, Twin Turret, Twin Spindle

-

The DA300 5-Axis Vertical VMC, inspired by top design elements from both vertical and horizontal machines, reduces machining time for complex production parts by offering high productivity in a compact footprint. It's ideal for single-setup, multi-side accessibility, or full contouring tasks, suitable for industries like hydraulic and pneumatics, optical, electrical & semiconductor, medical & dental, die-cast, automotive, aircraft, and aerospace, as well as contract job-shop work.

Makinos DA300, 5-axis, 15 hp, 60-tool turrets, 12” Trunnion Table